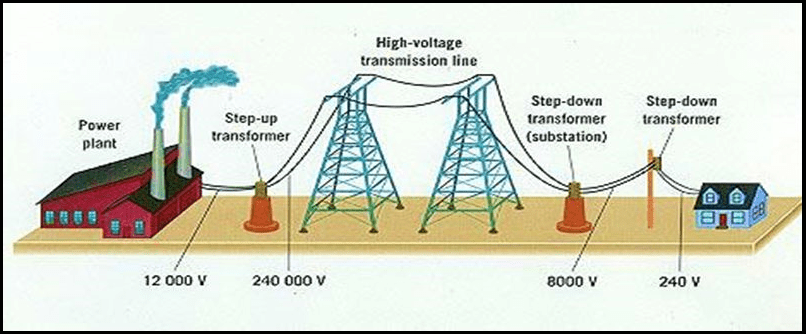

Power is generated at a voltage in the hundreds of thousands, but our home appliances usually clock in at just 110-250V. Since electrical pylons carry electricity that is more than a hundred times more powerful than what your home appliances need, plugging your phone charger or washing machine directly into it would make them explode. Even power-hungry factory equipment use around 10% of the electricity running through power lines. So how do we keep our electrical devices (and ourselves) plugged in?

If you’ve ever wondered how electricity safely goes from power plants, through the streets, and into your homes, you have electrical transformers to thank.

What are transformers?

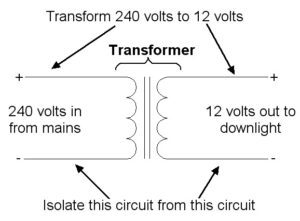

As the name implies, these electrical devices take electricity from one source, transform its voltage, then transfer that energy to another circuit. Transformers are often used to distribute power across long distances.

Transformers are used virtually everywhere, including power generation plants, industrial factories, commercial spaces, and residential areas. They can be as tall as a multi-storey building, or even small enough to fit inside an electric toothbrush.

Transformers work through electrical induction, which means that they direct electricity through a changing magnetic field. They produce heat, which is why your appliances get warm after they’ve been on after a while.

Why do we use transformers?

While there are many reasons for the modern world to use transformers, the main two are convenience and cost.

No other electrical device functions in the same way as a transformer. Transformers don’t actually generate power, but they do help distribute it to other locations efficiently and safely. Compared to other systems, transformers have less waste when transferring energy, which makes it very useful for distributing power to far-away places.

The energy that a power generating plant supplies is used for a variety of purposes, powering up everything from factory machines to small homes. Each setup has its own electricity and voltage requirements. It’s much easier to produce high-voltage electricity, then use transformers to change it to a lower voltage as needed.

How do transformers work?

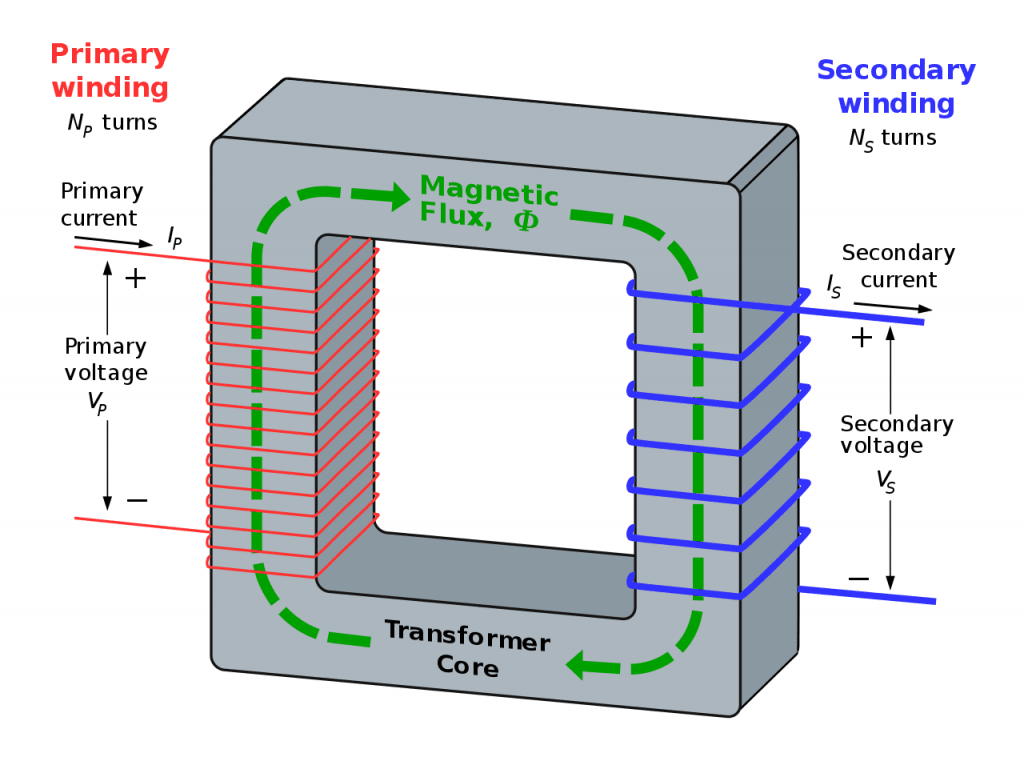

A basic transformer has four main parts:

Input connection – This is the side where the power source to be transformed is connected, also called the primary side.

Output connection – The second circuit is connected to the output connection. The transformed energy flows out of here; depending on what is required, the voltage is either higher or lower than the power coming through the input connection.

Windings – Windings are made up of at least two coils. The first coil, connected to the power input, is called the primary coil. The secondary coil delivers the transformed electricity to the output connection. These coils can be further subdivided into more coils to reduce flux and provide more power.

Core – The core is the material through which the current can pass through. It provides a controlled path for the magnetic flux. This can be made out of multiple, thin sheets of laminated steel (iron core) or non-magnetic materials (air core).

When an electrical current flows from the input connection to the primary coil, it creates a magnetic field around the coil. If you place a secondary coil next to the first one, that coil gets impacted by the magnetic field, making it have a current as well. This is called electrical induction.

The windings determine how the voltage is transformed within the device. Each coil has a specific number of turns; to change the voltage, the secondary coil needs to have either more or less turns than the primary coil. The ratio of the turns is what decides the output voltage. If the secondary coil has more turns than the primary, the output voltage will be greater. If it has fewer turns, then the output voltage will be lower.

For example, your input voltage is 30V, and the primary winding has 2,000 turns. The secondary coil has 1,000 turns or half the number of turns of the primary winding. This means that the output voltage will also be half that of the input voltage, resulting in a 15V output. A simple formula to remember this is:

# of Turns in the Primary Coil = Input Voltage

# of Turns in the Secondary Coil Output Voltage

Because of the nature of transformers, all of them produce waste heat. If it gets too hot, the transformer can overheat, sustain damage, and make it less reliable. This isn’t usually a big problem with small items like chargers, but bigger machines with higher voltage demands can run into this issue. To help reduce the risk of overheating, many transformers are designed to keep temperatures balanced and may have built-in cooling systems.

Types of transformers

There are different ways of classifying transformers, like based on voltage or usage.

Voltage

The most common and widely-used classification of transformers is by voltage. There are two kinds: step-up transformers and step-down transformers.

Step-up transformers are transformers where the secondary coil has more turns than the primary coil. This means that the output voltage will be higher than the input voltage, thus the name “step-up.” These can be found in power plant generators connecting to power grids.

Step-down transformers are the opposite: the secondary coil has fewer turns than the primary coils. The output voltage will be lower than the input voltage. This converts the high-voltage power from the power plants to a lower, more usable level for offices, homes, and factories.

Usage

Different-sized transformers are used for different levels of input and output. Bigger transformers (like those in power systems) can often handle much higher voltage transfers than smaller ones (like those found in home appliances).

Power Transformer – Power transformers are used in power generation plants and transmission substations. They can handle very high voltages, more than 33,000V.

Distribution Transformer – Smaller than a Power Transformer, a Distribution Transformer is less efficient and handles lower voltages, but it’s also easier to install. These are used for the distribution of energy as low as 110-220V.

Transformers can also be classified according to core materials, windings, and supply.

Electrical transformers are a major technological innovation that has provided us with safe, efficient energy that can be used for a wide range of purposes. Thanks to the induction process, we can hook up our appliances and equipment – all with different voltage requirements – to the grid without worry.

We hope you found this article informative. Remember if you need help with understanding transformers or have any general electrical questions then please contact our friendly and licensed Electrical Perth Contractors.

Contact us today on (08) 9220 5201